Product

1. Disperse evenly and defoam perfectly within five minutes.

2. The self-rotating speed can be set freely, and the material has the widest applicability.

3. Double cup stirring at the same time, double the production capacity.

4. Double motor design, high specific gravity materials can be evenly dispersed.

5. No-blade contact design does not pollute raw materials and improve yield.

Purpose:

Mix, disperse one or more raw materials uniformly

Brand: CGT

Model: MJ-300V, MJ-600V, MJ-1000V, MJ2000V (If the mixing amount needs to be larger, please call us)

Are you still using traditional mixing methods?

Time-consuming and uneven mixing bothers you

Are you still using a vacuum oven or standing for a long time to remove bubbles?

Time-consuming, micro-nano bubbles are not cleanly removed is a pain point that you have never been able to solve

These two major pain points, one machine can quickly get it done!!

"Planetary Vacuum Defoaming Mixer"

Five minutes, quickly complete uniform stirring & perfect defoaming

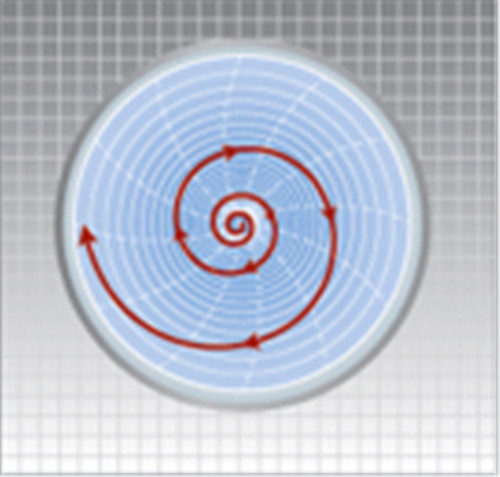

How it works:

The shearing force generated by the rotation and the centrifugal force generated by the revolution, plus the effect of the vortex state and torque generated by the up and down convection, allow the material to be fully stirred and mixed in a very short time. When this kind of movement is carried out under vacuum, the volume of fine bubbles expands rapidly by 760 times, and is removed at the interface in contact with vacuum (133pa=1torr), so it can be completely defoamed and stirred evenly in about 3 to 10 minutes. . (The actual time needs to be slightly different according to the characteristics of each material, such as viscosity and stirring amount.)

Operation legend

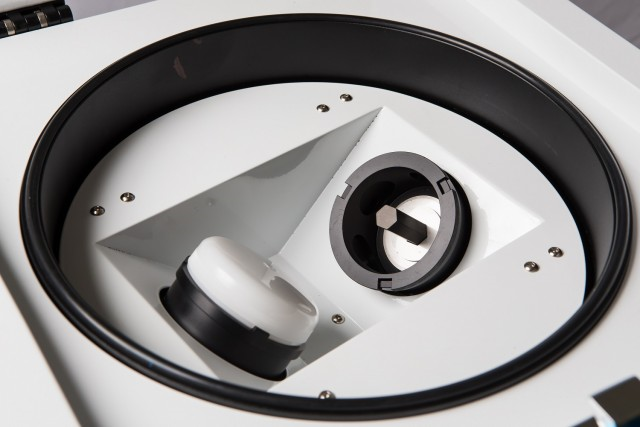

Example of internal installation of the blender jar (single and double blender)

Application areas:

LED (A, B glue + phosphor), PCB printed circuit (green paint, solder paste), TP touch panel (silver paste, conductive paste), LCD panel (UV glue, liquid crystal), solar panel (silver paste, (Silver aluminum adhesive), electronic parts (thermosetting encapsulant), automotive industry (sensing product materials), semiconductor packaging and testing (wafer fixing silver adhesive), biotechnology medical (biological reagents, artificial joint materials)

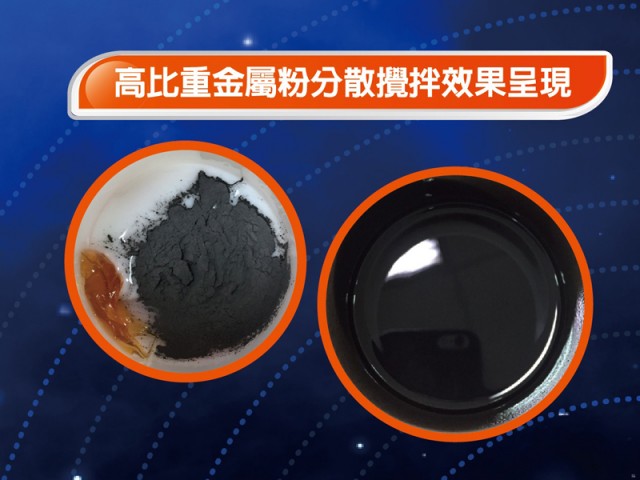

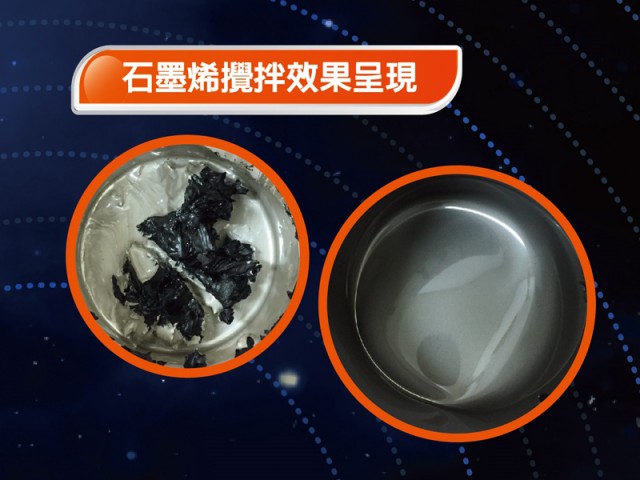

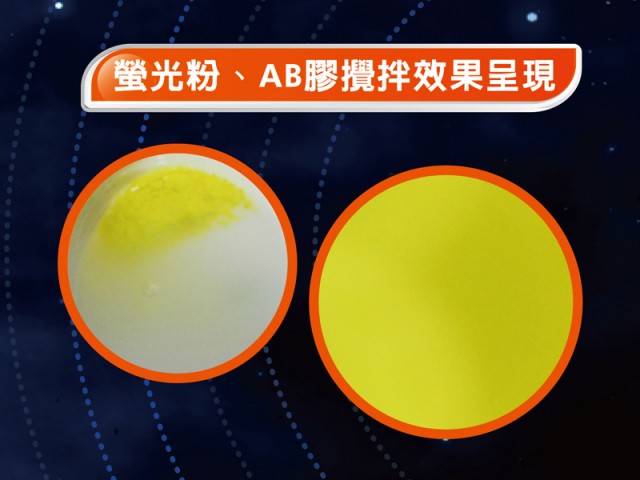

Actual mixing effect

Sample(From left to right): High specific gravity metal powder, graphene and resin, fluorescent powder and AB glue

|

|

|

|

1.Using biaxial centrifugation and vacuum pump with high efficiency, Vacuum Defoaming Mixer mixes a variety of raw materials well, and removes Nanoscale tiny bubbles effectively.

2.With the unique design of double motors and high torque, Vacuum Defoaming Mixer also evenly disperses fluorescent powder or other higher-proportioned raw materials under the condition of non-settlement.

3.Vacuum Defoaming Mixer stirs double cups simultaneously, so it increases double capacity and reduces consumption of production time. Its design of no leaf contact doesn’t pollute raw materials, and increases product yield significantly.

4.With the unique design of high efficiency and low power, Vacuum Defoaming Mixer controls the temperature around 24~25 ℃after the raw material is stirred. It also takes only four minutes to finish defoaming high viscosity material, which is very efficient.

5.Vacuum Defoaming Mixer adopts man-machine operation. Production line staff can set the memory parameters according to different viscosity of the glue. The memory parameters can be memorized up to 20 sets.

6.Vacuum Defoaming Mixer has fault warning light, a safety door, and vibration protection device to ensure the safety of the operator and the mixer itself

MV-300S

|

|

MV-600S

|

|

Blender capacity:150ml X 2 Vacuum flow: 85L/min Machine size : 600mm x 400mm x 600mm Machine weight:65 Kg |

|

Blender capacity: 300ml X 2 Vacuum flow: 140L/min Machine size: 620mm x 410mm x 600mm Machine weight:65 Kg |

|

Detailed specifications:

1. Transmission mode: gear transmission

2. Mixing mode: single cup or double cup can be stirred at the same time

3. Motor specifications: Two sets of 750W servo motor

4. Motor control: revolution (motor alone controls speed) autorotation (motor controls speed independently)

5. Revolution speed: 100~1500 rpm

6. Rotation speed: 1~100% (1~1500rpm)

7. Operating environment: 10~30℃, 35~80%RH

8. Vacuum: 0.1 torr

9. 20 sets of parameters can be stored

10. Time setting: 1~600sec (three steps)

11. Power supply: single-phase AC220V±10%50/60HZ 12A

12. Digital Touch HMI, PLC

13. Operation page password lock, vacuum start delay setting, equipment regular maintenance setting

14. Vacuum digital display

15. Abnormal detection buzzer

16. Safety door induction detection, vibration induction detection, motor abnormality detection, vacuum abnormality detection

17. The unique dual-motor and high-torque design, the mixing of raw materials with higher specific gravity, can also be dispersed evenly without sedimentation.