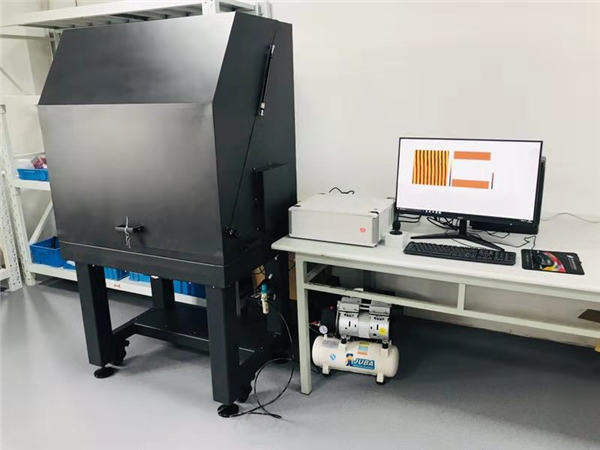

Product

1. Large size scan ----- can measure the largest sample to 12 inches

2. Programmable electric control sample stage

3. The highest cost performance

4. High rigidity design and anti-vibration system----easy measurement at any time and place

5. Get nanometer surface features quickly and accurately-you can get high-resolution images in five minutes

Purpose:

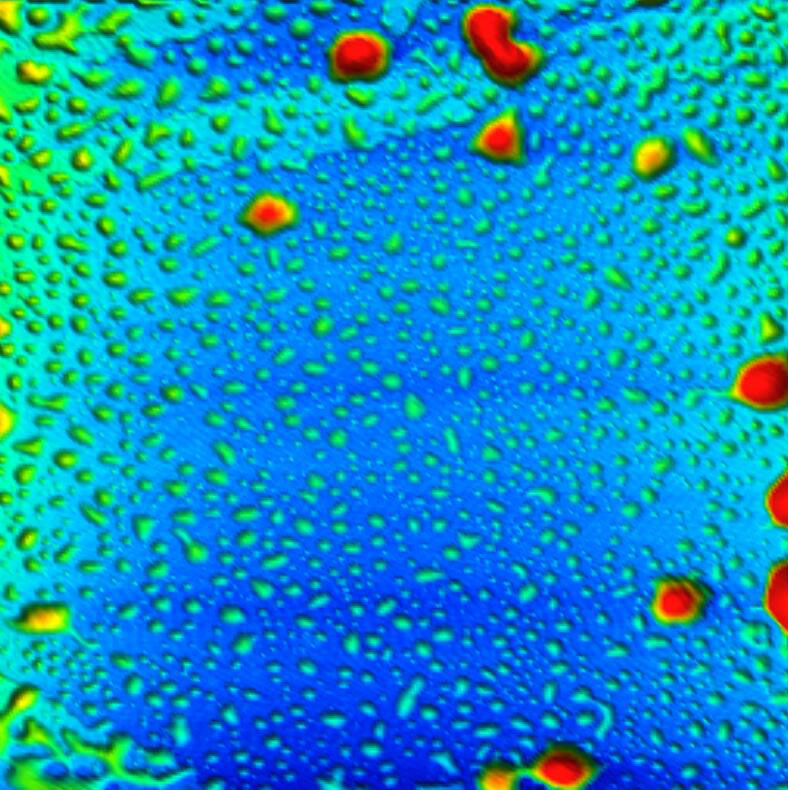

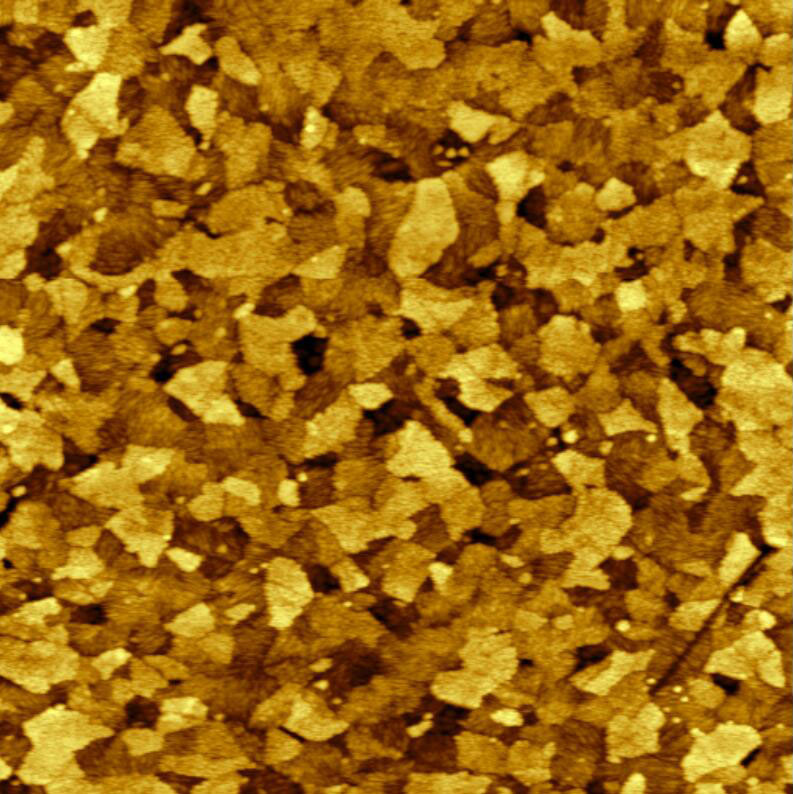

Provide three-dimensional surface morphology images, including surface roughness, particle size, height difference and spacing

Brand: FSM

Model: LS-AFM

The most intuitive, fast and cost-effective industrial AFM,

4”-12” samples can be tested directly on the machine without damage,

Set the coordinate automatic positioning, so that you can easily measure,

The best weapon for product development and quality control!

Alumina Al₂O₃

Alumina Al₂O₃

STO film

STO film  ITO film

ITO film

Features:

1. Provide 6-inch or 12-inch sample measurement without sample weight limitation.

2. Ultra-long travel two-dimensional electric sample moving table, quickly input the coordinates for the position to be measured and then automatically position the lower needle.

3. Gantry scanner design, with marble base and vacuum adsorption stage.

4. Motor control and piezoelectric ceramic scanner automatically detect the needle feeding method, effectively protect the probe and sample.

5. Automatic optical positioning, no need to adjust the focus, observe and locate the probe sample scanning area at any time.

6. The most cost-effective industrial AFM with large stage

1. Evaluate the difference before and after wafer processing (SiO2, GaAs, SiGe, etc.)

2. Determine the treatment effect of biomedical equipment (eg plasma treatment), such as contact lenses, catheters and coated stents

3. Check the effect of surface roughness on adhesion

4. Evaluate the groove shape and cleanliness of the patterned wafer

1. Coating analysis: roughness analysis, film thickness analysis, hole size analysis

2. Nano material analysis: particle size analysis, dispersion analysis

3. The surface structure can be converted into 3D images, which can quickly solve the material structure and morphology.

4. Material surface elasticity distribution, frictional force distribution, charge distribution, magnetic area distribution analysis, etc.

Specifications:

Basic mode: Tapping, Contact. Options: Phase, MFM, EFM, LFM

Scan rate: 0.6Hz~4.34Hz

Force graph curve: F-Z curve, RMS-Z curve

Scanning angle: 0~360°

Optional mode: Profile line fast measurement mode

Operating system: Windows XP/7/8/10 operating system

Scanning range: XY: 50um, Z: 5um

Communication method: USB2.0/3.0

Scanner resolution: XY: 0.2nm, Z: 0.05nm

Shockproof design: air-floating shockproof table/metal soundproof box

Sample size: Φ=150mm (6 inches), 300mm (12 inches), H<20mm

Equipment size: 800×600×500mm

Equipment weight: 150Kg

Sample moving range: 300×300mm

Optical microscope specifications 10X objective lens/1um resolution