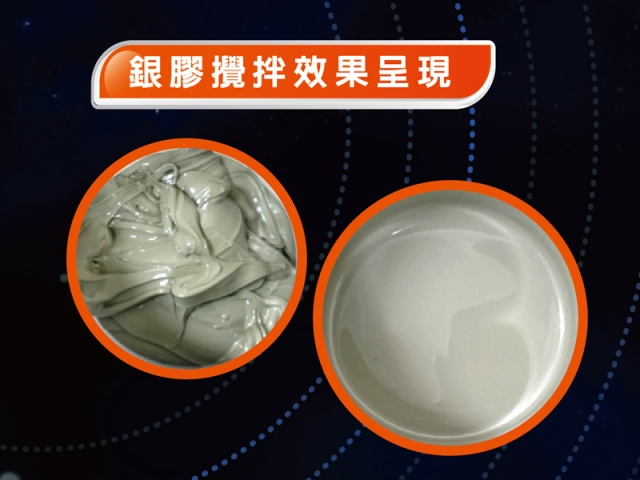

Conductive silver glue

Conductive adhesive: also called conductive silver adhesive, which is composed of conductive filler and silver-copper, and has certain conductive properties after curing or drying. It usually consists of matrix resin and conductive filler, namely conductive particles, as the main components. The bonding effect of the conductive particles is combined together to form a conductive path to realize the conductive connection of the adhered material. Since the base resin of the conductive adhesive is an adhesive, a suitable curing temperature can be selected for bonding. For example, the epoxy resin adhesive can be cured at room temperature to 150 ℃, which is far lower than the soldering of 200 ℃ for tin-lead soldering. Temperature, which avoids the material deformation, thermal damage of electronic devices and the formation of internal stress that may be caused by high temperature welding. At the same time, due to the rapid development of the miniaturization and miniaturization of electronic components and the high density and high integration of printed circuit boards, the minimum pitch of 0.65 mm of lead-tin soldering is far from meeting the actual needs of conductive connections. Can be made into a slurry to achieve a high line resolution. Moreover, the conductive adhesive has a simple process and is easy to operate, which can improve production efficiency and avoid environmental pollution caused by heavy metal lead in tin-lead solder. Therefore, conductive adhesive is an ideal alternative to lead-tin soldering to achieve conductive connection.

Original URL: https://read01.com/zh-tw/dEBzQGE.html#.XsD4Im5uKhI