產品介紹

2. Direct measure conductivity σ & ε permittivity at the Nano-Scale

3. Linear relationship to electrical properties

4. Quantitative doping concentration mapping

5. Nano-Scale C-V spectra

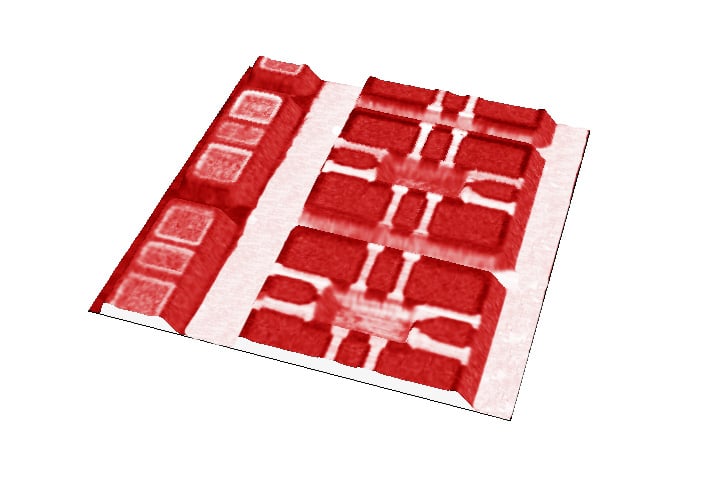

6. Sub-surface sensing capability

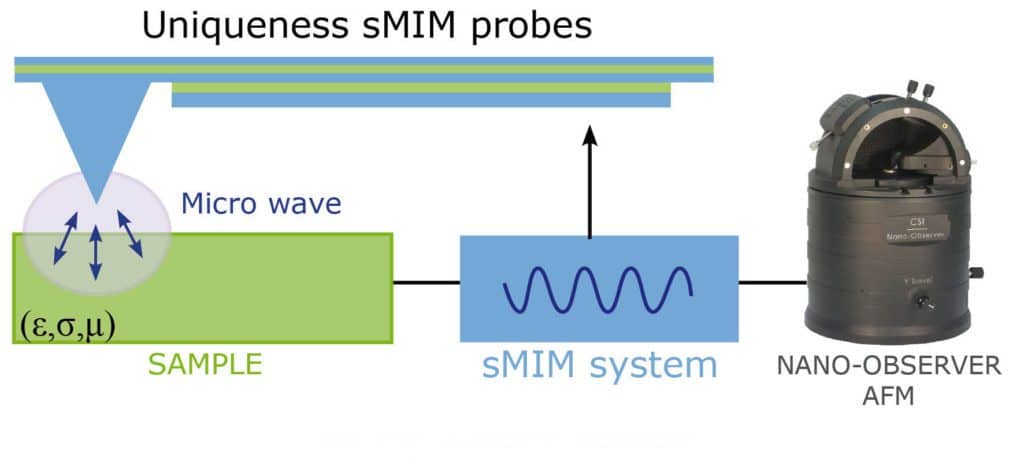

Principle

“Conductivity, Permittivity & N-Doping Concentration.”

How ScanWave™ Works

1. ScanWave™ sends microwaves to the probe tip via a fully shielded path.

2. The microwaves create a near-field electromagnetic wave at the the probe tip that interacts with the sample surface and subsurface.

3. After the near-field interacts with the sample, a portion of the microwave power is reflected back through the same shielded path to the ScanWave™ electronics for filtering, demodulating, and processing.

4. As the probe moves across the sample, the reflected microwaves vary in amplitude and phase due to variations in the local electrical properties under the probe tip.

5. The ScanWave™ software calibrates the reflected signal from the probe-sample interface to create a capacitive and a resistive image that are displayed by the AFM simultaneously with the topography image or images.

ScanWave Advantages

“Affordable solution for Nanoscale Mapping of electrical measurements.”

Unprecedented Sensitivity

Industry’s highest sensitivity lets you image the hard stuff. Industry’s lowest noise floor lets you see the small stuff.

Subsurface Imaging

Imaging of buried structures underneath the sample surface is possible thanks to the long range nature of sMIM.

No Conductive Path Needed

No ground or conductive path needed to get your electrical characterization.

Single scan – 6 channels of data

sMIM-C: Capacitance/Permittivity variation

sMIM-C: Capacitance/Permittivity variation

sMIM-R: Resistivity/Conductivity variation

sMIM-R: Resistivity/Conductivity variation

dC/dV Amplitude: Carrier concentration

dC/dV Amplitude: Carrier concentration

dC/dV Phase: Carrier type +/-

dC/dV Phase: Carrier type +/-

dR/dV Amplitude: Carrier concentration

dR/dV Amplitude: Carrier concentration

dR/dV Phase: Carrier type +/-

dR/dV Phase: Carrier type +/-

Minimal Sample Prep Time

Since it is not necessary for the sample to be in a conductive path or under current flow or even for the feature of interest to be exposed, samples can be imaged with minimal prep tim

Contact and Non-Contact Mode Imaging

Electrical measurements can be made in tapping contact imaging modes, even during force distance curves. However you want to scan, ScanWave™ can get the electrical data you need.

Nano Resolution

Transform your AFM into a high resolution, nanoscale local electrical property microscope.

Simultaneously

Be it conductors, semi-conductors, dielectrics, or insulators, ScanWave™ can handle it all. Different materials, even of different classes, can be imaged in the same scan.

Easy to Use Software

Scan management and configuration is a bliss.

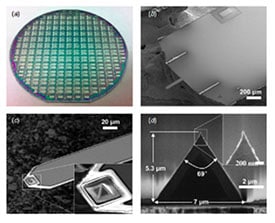

sMIM probes

The sMIM probes are batch fabricated MEMS devices (micro electrical mechanical systems) with a shielded front and backside and center transmission line.The probe shielding reduces stray coupling from the environment and the cantilever. The probe radius is nominally 50nm to optimize signal strength and lateral resolution.The probe sample interface use a resistor and capacitor in parallel. This “leaky capacitor” presents an impedance mismatch to the 50 ohm system electronics, creating a reflection.

As the sMIM probe is moved across the sample surface there is a change in the impedance of this leaky capacitor and the resulting change in the real and imaginary parts of the reflected wave are output as two signal from the ScanWave electronics. These signals are digitized by the AFM to produce the sMIM-C and sMIM-R images synchronized with the topography images.